Завод по производству металлоизделий

Металлоизделия

Металлоконструкции

Завод мелкосерийных изделий - это изготовление металлоизделий и конструкций под заказ.

Для нас нет ограничений по сложности проектов – специалисты справятся с любой задачей. Мы также можем разработать всю необходимую техническую документацию.

С большим опытом беремся за изготовление металлоизделий и конструкций по чертежам клиента.

- Мебель, уличные навесы, оборудование;

- Заборные и пешеходные ограждения;

- Велопарковки, указатели;

- Уличные навесы, павильоны;

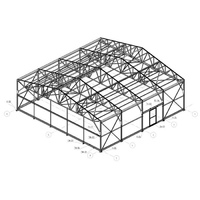

- Балки перекрытия, стальные фермы;

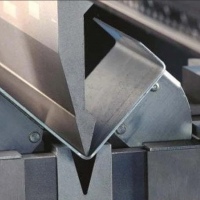

- Фахверки, колонны, кронштейны;

- Прогоны; связи;

- Плоские фланцы, гнутые изделия.

Наш завод полностью оснащен оборудованием, необходимым для полного цикла производства.

Изготовление изделий из металла на заказ

- Производство нестандартных изделий, проектов.

- Работа по готовым чертежам, разработка документации с нуля.

- Современное производство полного цикла.

- Реализуем в готовые проекты даже эскизы «на салфетке».

Услуги по обработке металла

- Первичная обработка металла.

- Резка металла (плазморезка, рубка на гильотине, абразивная, лазерная, ленточная).

- Любые работы по гибке и формовке металла.

- Вырубка металла.

- Сварочные работы – аргоном, автоматом или полуавтоматом.

- Покраска и обработка металлоизделий.

Продажа металлопроката

У нас Вы можете также купить прокат из нержавеющей стали. У нас вы найдете даже редкие позиции. Размер поставки не ограничен: реализуем оптом и в розницу.

- Листы, трубы, рулоны;

- Квадраты, шестигранники;

- Уголки, швеллеры;

- Детали для трубопроводов;

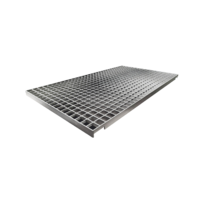

- Комплектующие для лестниц;

- Проволока и электроды.

Почему с нами работают:

Производство

Собственные производственные мощности, расположенные в Московской области.

Охват

Большая география – у нас есть филиалы во многих крупных российских городах – Санкт-Петербурге, Воронеже, Ростове-на-Дону, Казани, Саратове и прочих.

Доставка

Сотрудничаем с крупными фирмами-перевозчиками, поэтому заказы доставляются к клиенту быстро.

Профессионализм

Можем воссоздать любые металлоконструкции по обычному фото или эскизу, беремся за выполнение нестандартных задач.

Качество

Дотошно относимся контролю, чтобы Вы были уверены в качестве изделий.

Сервис

Полностью закроем Ваши потребности от проектирования до финишной обработки, покраски.